Connects disparate devices and applications, from plant control systems to enterprise information systems

LinkMaster provides a means of linking data between OPC servers, thus serving as a universal bridge for OPC systems. LinkMaster acts as both an OPC server and DDE server, allowing it to bridge legacy DDE systems and new OPC-enabled applications.

Programming Knowledge Optional

LinkMaster is a fast and robust Windows application that requires no programming knowledge. Simply “Drag and Drop” to create your links. Built-in scaling, user-access manager, error tracking, and write optimization capabilities provide total control of your data flow and application access.

Control Data Transfers With Link Groups

Link Groups are used to form collections of OPC items that will be moved between OPC servers at a specified rate. Using multiple Link Groups, LinkMaster allows you to control how fast data is transferred from one OPC server to another. By using Link Groups with different update rates, you can tailor your data transfers to fit the needs of the application. While one item may need to be sent at high speed, other items in the application may need slower update rates. Link Groups gives you that control. The benefit is reduced network traffic and increased reliability.

LinkMaster provides fully-featured data bridging, drag and drop link creation, error logging, support for creating Custom Remote Machine references, and more.

This feature allows a pair of LinkMaster machines to operate in redundant pairs where one LinkMaster machine operates as the “Primary” node and the other as the “Secondary” node. When the “Primary” node fails, the “Secondary” node promotes itself and takes over the role of the primary. When the “Primary” node comes back up again, the “Secondary” node demotes itself and the “Primary” node performs the data transfer once again.

Based on Microsoft’s COM technology, OPC servers can share data with remote client applications using DCOM (Distributed COM). DCOM allows you to use a single OPC server to provide data to client applications running both locally and on remote machines. DDE is not without its own means of allowing remote access. All of the DDE formats supported by LinkMaster can also be accessed remotely using what is known as NETDDE. NETDDE allows a remote DDE client application to use the machine name of a remote DDE server when specifying a DDE link. LinkMaster has been designed to allow both of these methods of remote server access. In terms of OPC connections, LinkMaster will properly configure your DCOM settings to allow remote OPC clients to access and browse LinkMaster. For DDE clients, LinkMaster will automatically start NETDDE services and register all of the required DDE shares, allowing remote DDE clients access to device data. Establishing DDE share names can be a time consuming process for the application, therefore, by default, NETDDE services are not enabled in LinkMaster.

LinkMaster supports running as a Windows service. Service operation is completely user configurable from the Tools|Options menu, and can be changed at any time allowing you to move from normal, stand alone program operation, to NT service mode. Running as a NT service is crucial for many applications where LinkMaster is providing data to OPC clients via DCOM. For these applications, loss of a DCOM connection can not be tolerated.

Normally, an OPC server that only supports stand alone program operation is forced to shut down when the host machine experiences a user log in or log out. While running as a service, LinkMaster can continue to supply OPC data across user log in sessions and can be configured to interact with the desktop, allowing you to make changes to your LinkMaster project. It can also be configured to have a non-visible presence while running.

LinkMaster supports direct scaling of link item data. Scaling allows raw data to be converted to engineering units for OPC client applications. LinkMaster provides a number of unique scaling features, such as Linear and Square Root formula scaling. You can also specify the range of the raw data input and the engineering range of the scaled value.

In some cases, the raw data input received may exceed the range set for the raw data. If this occurs, the engineering value can be forced outside of the range you desire. To prevent this, LinkMaster allows you to clamp the scaled value to the engineering ranges. In most cases, it is always assumed that a scaled value results in a floating point number. LinkMaster doesn’t make this assumption and allows you to select the scaled engineering value to be any valid OPC data type. This means you can scale a 16-bit integer value to a 32-bit integer value.

LinkMaster’s link management system allows you to create a Link database structure that fits the nature of your application. Multiple Link groups can be added and defined to segregate your Link items into meaningful groups. Drag and drop editing makes adding a large number of tags easy. Unique Link Management features allow new links to be created on the fly using convenient “Drag and Drop” and “Tag Browsing” methods.

In certain situations, managing what your users can and cannot do in your OPC application can be a necessity. LinkMaster includes a built in User Manager that allows complete control over what types of functionality each individual user can access. The default administrator account allows you to add multiple users, each with their own set of rights for LinkMaster access. Any user log in/log out is recorded in LinkMaster’s event logging system, the EventViewer. By default, all operations are available at all times until you decide to set privileges.

Included with the LinkMaster package is a stand alone event monitoring application called the EventViewer. The EventViewer is a 32-bit Windows application that monitors and displays events occurring on any running LinkMaster application, either remotely or locally, allowing multiple LinkMaster systems to be monitored concurrently.

The most common scenario for LinkMaster is to link data between two (or more) OPC servers. As an example, a customer might be using RSLinx for connectivity to Allen-Bradley PLCs and Kepware’s U-CON driver for connectivity to a checkweigher. In this example, the customer wants to easily send scale data to the PLC.

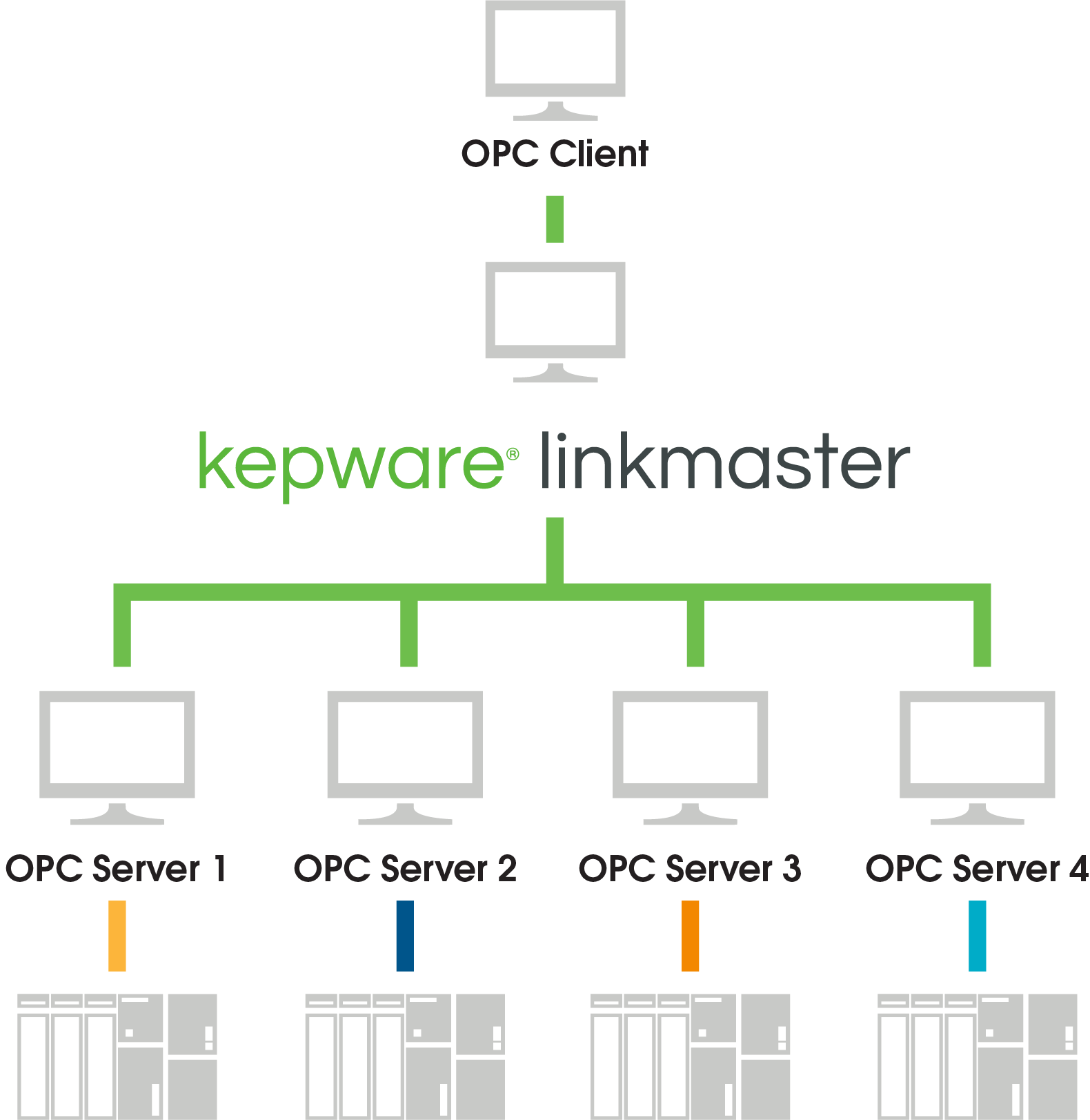

Another interesting application for LinkMaster is functioning as a single OPC server that serves data from multiple OPC servers. This approach demonstrates LinkMaster’s capability to act as both a client and a server. As an example, a customer might have a single OPC connection available from an OPC client application, but have multiple OPC servers from which he or she needs to acquire data.

This scenario is commonly used when a customer wants to route data between two PLCs connected to the same server. Using LinkMaster to define the tag data routing can be much easier than creating new ladder logic in your PLCs (especially for legacy systems). As an example, a customer might be using KEPServerEX to connect to an Allen-Bradley ControlLogix PLC as well as a Yokogawa DX Data Recorder.

DTL Systems Limited is a Connected with Kepware® Preferred Distributor in Ireland. As a Connected Preferred Distributor, DTL Systems Limited promotes, distributes, and offers local support and training for all software solutions across Kepware’s product portfolio outside of North America.

@Kepware is a software development business of PTC Inc. located in Portland, Maine. Kepware provides a portfolio of software solutions to help businesses connect diverse automation devices and software applications and enable the Industrial Internet of Things. From plant floor to wellsite to windfarm, Kepware serves a wide range of customers in a variety of vertical markets including Manufacturing, Oil & Gas, Building Automation, Power & Utilities, and more. Established in 1995 and now distributed in more than 100 countries, Kepware’s software solutions help thousands of businesses improve operations and decision making. Learn more at https://www.kepware.com/.