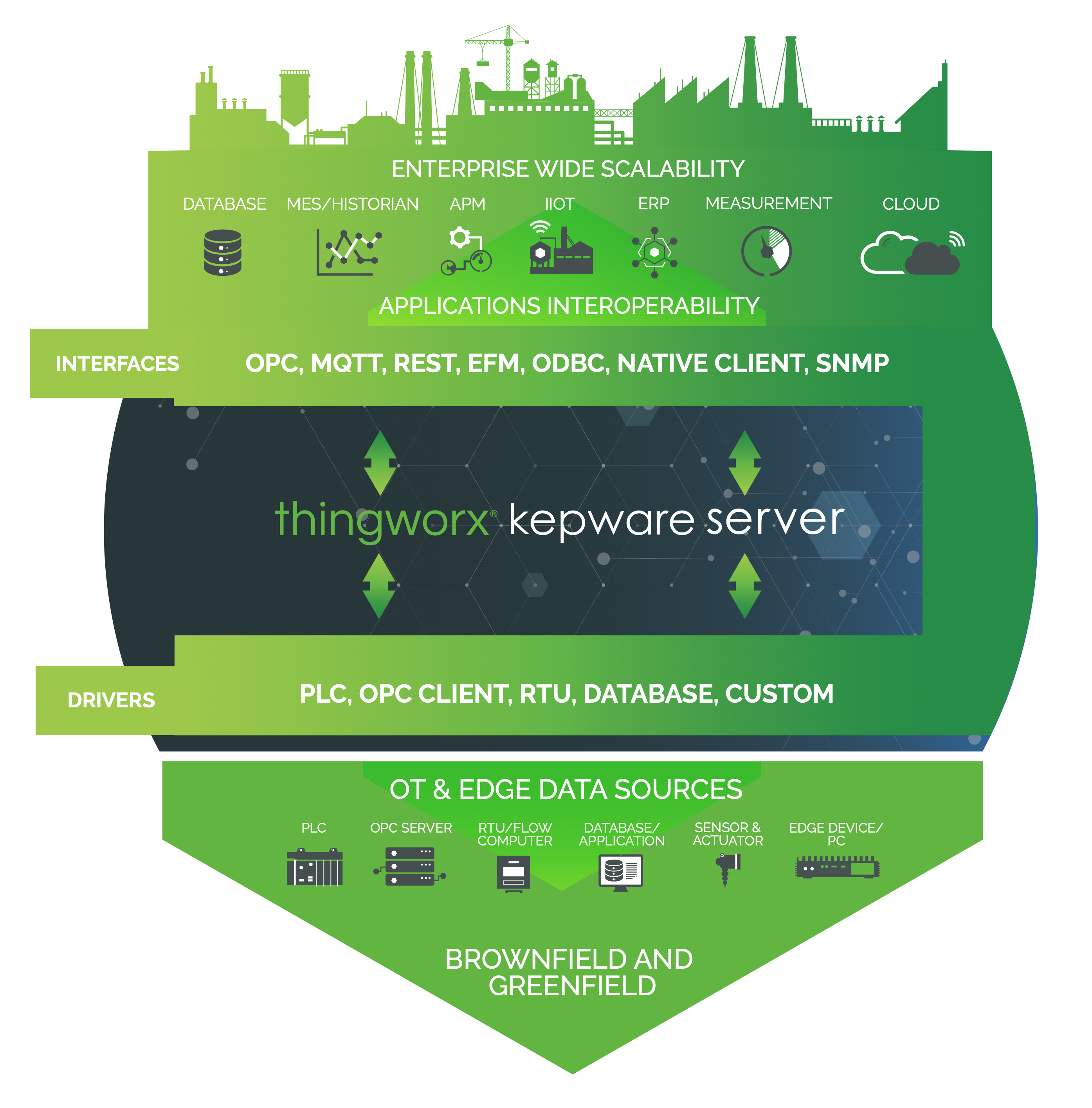

Connects disparate devices and applications, from plant control systems to enterprise information systems

Many industrial companies fail to scale IIoT projects and get stuck in what has been termed Pilot Purgatory. The last mile challenge of bringing together complex, ad-hoc heterogeneous data connectivity architectures with old, unconnected machines and siloed data is often what keeps them from progressing.

TKS (Enterprise Licencing) solves this. No matter where the data is, the interoperable platform makes it accessible to a broad range of environments including SCADA, MES, ERP and IIoT. This accelerates the time to value by simplifying digital transformation projects, extending connectivity to legacy machines and equipment, and providing the flexibility to get ahead of IIoT deployments by connecting factories in advance.

The new enterprise connectivity platform includes access to all Kepware drivers, protocols, and advanced plugins—providing a single, robust interface to industrial data across your entire enterprise.

Streamlining connectivity across all factories is vital to achieving digital transformation and drastically reducing implementation time. Enterprise level connectivity from our platform enables simplified and standardized connectivity between the diverse automation devices and sensors across all factories and operations environments—to your preferred IT solution.

Built by connectivity experts at PTC and trusted at over 75,000 sites, our enterprise wide connectivity platform provides a reliable, scalable, and secure architecture. This ensures Industry 4.0 projects stay on schedule and on budget, improves the security of your operations/OT network, and covers connectivity needs today and into the future

Interoperability:

The interoperability of the platform quickly and easily connects, aggregates, and optimizes data from diverse automation devices and sensors—making the data easily accessible to a broad range of IT and OT systems (IIOT, ERP, SCADA, MES, etc.)

Speed and Reliability:

Connect to devices in minutes so you can quickly collect data that both OT and IT can use as the “one source of truth”—without writing or maintaining custom code or interrupting production. Rely on technology that has been trusted by engineering and operations for over 20 years.

Scalability:

Connect to almost any asset on the plant floor, so you can easily scale within and across factories. With standardized data access to IT applications, you’ll no longer need to waste time creating custom connectivity for each new asset or facility.

Security:

Improve cybersecurity by converting insecure protocols to secure protocols, minimizing attack surfaces, and fostering segmentation of the operational network.

Support:

A team of dedicated and award-winning connectivity experts are at the ready to ensure your projects stay on track

The interoperability of TKS (Enterprise Licence) provides the foundational element to any Industry 4.0 or connected operations solution. In addition, it includes a native interface to the ThingWorx IIoT Platform.

DTL Systems Limited is a Connected with Kepware® Preferred Distributor in Ireland. As a Connected Preferred Distributor, DTL Systems Limited promotes, distributes, and offers local support and training for all software solutions across Kepware’s product portfolio outside of North America.

@Kepware is a software development business of PTC Inc. located in Portland, Maine. Kepware provides a portfolio of software solutions to help businesses connect diverse automation devices and software applications and enable the Industrial Internet of Things. From plant floor to wellsite to windfarm, Kepware serves a wide range of customers in a variety of vertical markets including Manufacturing, Oil & Gas, Building Automation, Power & Utilities, and more. Established in 1995 and now distributed in more than 100 countries, Kepware’s software solutions help thousands of businesses improve operations and decision making. Learn more at https://www.kepware.com/.